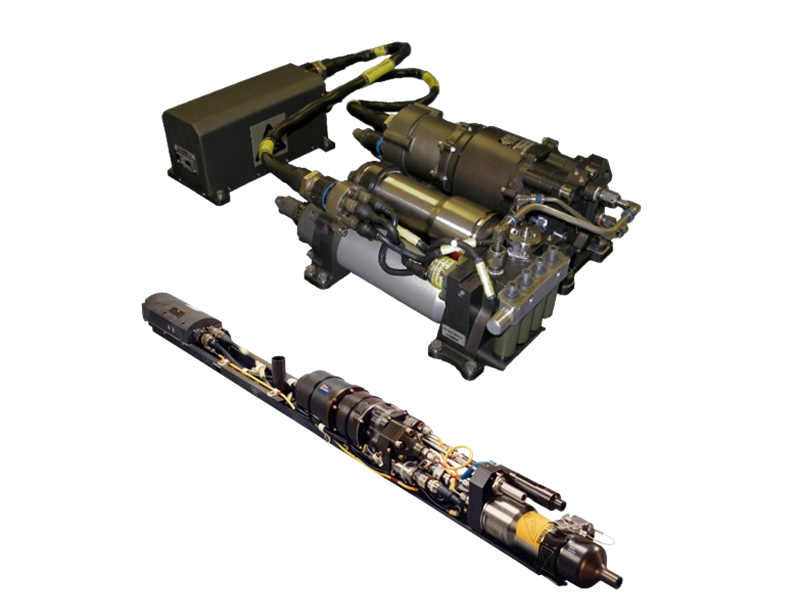

Ultra PCS is the leading manufacturer of compact on board gas solutions including our high performance HiPPAG™ compressor, sealed for life Gas Vessels and efficient Ejector Valve Assemblies for Stores Ejection.

Our HiPPAG™ system has two primary applications:

- Providing high pressure cold gas for the clean, reliable and repeatable ejection of stores from military aircraft

- Providing high pressure pure gas for missile seeker cooling without the logistics footprint associated with refillable gas canisters

Ultra PCS provides a range of storage and control products to enable the integration of cold gas systems in to a wide range of platforms.

Generate

Our HiPPAG™ 500 Series systems are designed to meet the demanding requirements of precision ejection systems and provide flexibility of installation within ejector racks, aircraft pylons or in internal weapons bays on high-performance manned and unmanned military aircraft platforms.

- Minimises logistics footprint by eliminating the need for pyrotechnic cartridges, other single-shot devices and their associated support equipment

- Continuous control of system pressure ensures an accurate and repeatable separation of store from

aircraft

HiPPAG™ 300 Series systems provide reliable always available pure gas for missile seeker cooling applications.

- HiPPAG™ eliminates the need for gas bottles with their associated logistics chain and so reduces lifecycle costs

- Pure gas is always available, the pilot no longer needs to worry about gas management

Store

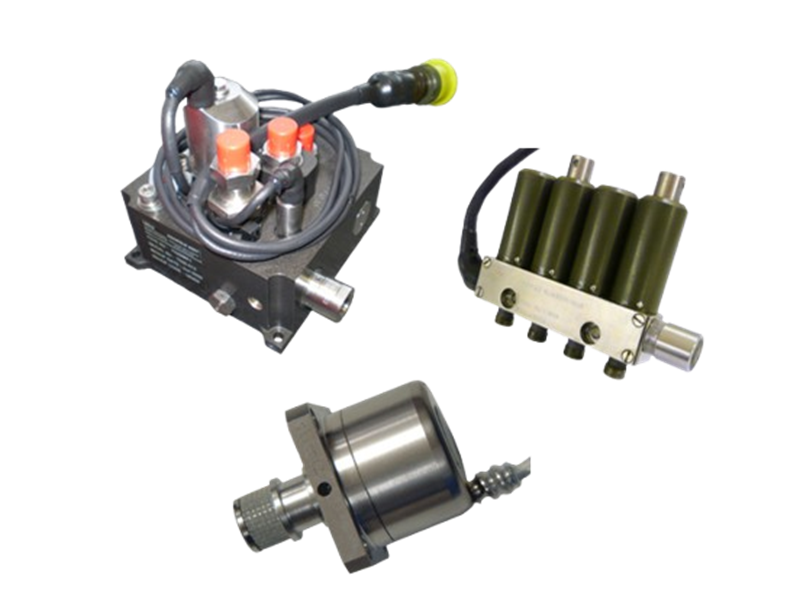

Ultra PCS offers Ejector Valves and Accumulators:

- Designed to fit within an Ejector Release Unit (ERU)

- Receives and stores the high-pressure dry air produced by the HiPPAG™ or ground charge system

- Typically 0.2 to 0.7 litres based on the store size and end-of-stroke velocity requirements

- A pressure balanced servo mechanism and dual-coil firing solenoid valve releases the gas to the ejector rams

- EVA pressure transducer relays the air pressure in the EVA to the aircraft

- Manual vent valves are provided to safely depressurise the EVA for maintenance

Ultra PCS offers a range of high-pressure vessels for the storage of pure air, nitrogen or argon gases. These are in operational use for cryogenic cooling, cold gas actuation and fuel tank pressurisation.

- Bottles can either be single use sealed for life or refillable through a solenoid valve

- Volumes range from a few cubic centimetres up to 2.4L

- Mainly stainless steel or titanium

- Designed to military standards

- DEF-STAN 81-91 or DEF-STAN 00-970

Control

Ultra PCS offers a range of products to integrate cold gas systems on to a platform, including:

Solenoid valves and mechanical valves

- Distribution manifold

- Coalescer dump valves

- Delivery valves

- High and low pressure relief valves

- Back pressure maintaining valves

- Pressure regulators

Deliver

High pressure flexible hoses:

- Specifically designed for the transfer of high-pressure dry gasses across dynamic structures in demanding aerospace and defence applications

- Ultra PCS hoses remain fully flexible even when pressurised to 414bar and at temperatures as low as -50°C

- Supplied with industry standard pneumatic connections or a novel high pressure quick disconnect based on a MIL-DTL-38999 connector

- Qualified to MIL-STD-810 requirements and thousands of make/break operations and tens of thousands of flex operations while fully pressurised and at operating temperature extremes of hot and cold